What are soldering robots?

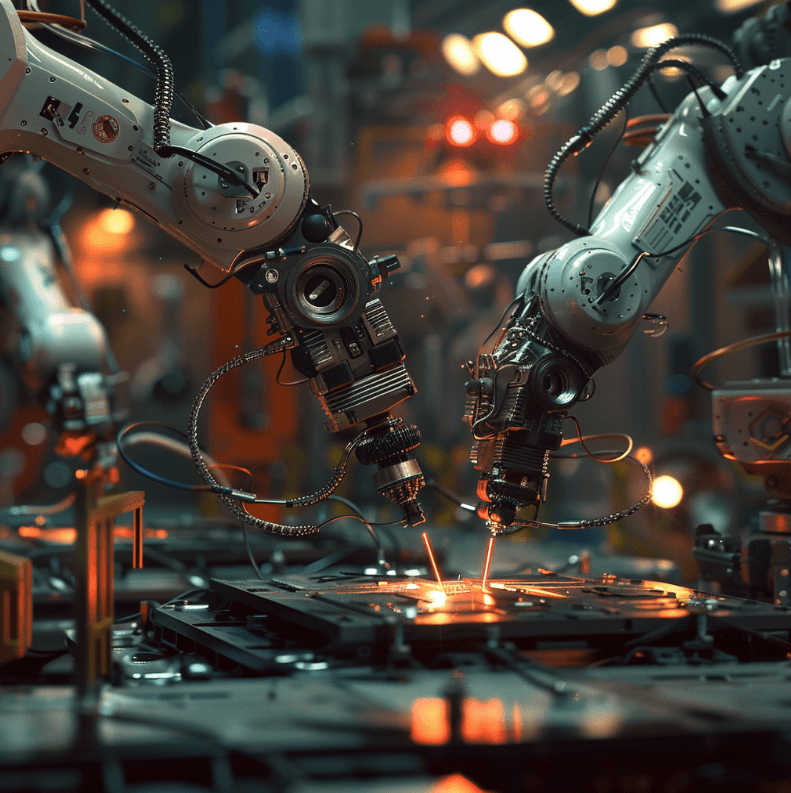

Soldering robots are automated systems that can (as their name suggests) solder components onto printed circuit boards (PCBs) with superhuman precision and speed.

To do so, they use robotic arms fitted with soldering irons to complete their tasks according to programmed instructions.

How do these robotic soldering machines work?

The robots work based on 3D models that show where each component should be placed. Specialized software then controls the robotic arm to pick up components and solder them accurately onto the PCBs.

The robotic arm can rotate and move in multiple directions to access any part of the PCB.

The main features of soldering robots

Soldering machines — and soldering robots, in particular — work with an array of complex electronics and high-end artificial intelligence (AI) systems.

Let’s take a closer look:

- Flexible manipulators. Multi-axis robot arms allow soldering robots to access hard-to-reach areas. The arms can rotate, extend, and bend to maneuver the soldering iron.

- Super-high degree of control. Soldering robots are programmed to precisely control the amount of heat and solder applied. They can consistently produce high-quality solder joints.

- High-end automated vision. Built-in cameras and sensors help the robot to identify solder points and properly align the soldering iron. Vision systems guide the robot to the correct location and detect when the soldering is complete.

- Flexible and programmable. Soldering robots can be programmed to perform repetitive tasks, freeing up human workers. Once programmed, the robot can complete the same soldering operations over and over with a high degree of accuracy and consistency.

Applications of automated soldering

Soldering robots have a wide range of applications across diverse industries:

- Electronics manufacturing: Automated soldering is the “glue” that keeps electronics assembly together. Soldering robots are used for soldering surface-mount and through-hole components on printed circuit boards (PCBs) common in smartphones, computers, and other electronic devices.

- Auto industry: Automated soldering is necessary for reliable connections in automotive electronics, sensors, and control systems found in modern vehicles.

- Aerospace and defense: Automated soldering guarantees the precision and quality required for critical electronics in aircraft, satellites, and defense systems.

- Medical devices: Automated soldering has the accuracy and consistency needed for the delicate components and complex circuit boards found in medical devices.

- Consumer goods: Automated soldering streamlines the production of a wide range of consumer products, from home appliances to wearable technology, where reliable electrics are de rigueur.

Advantages of using a soldering robot

Soldering robots have plenty of benefits over plain old manual soldering:

- Robots can solder components much faster and more precisely than humans. Their mechanical arms have a high degree of dexterity and accuracy, allowing them to swiftly and reliably solder even the smallest components.

- Robots also produce higher quality, more consistent solder joints. They apply the perfect amount of heat for the optimal duration to achieve secure solder connections each and every time. This results in stronger, longer-lasting products with fewer flaws.

- In addition, soldering robots improve workplace safety by removing people from noxious fumes and high heat. Operators can control and monitor the robots from a safe distance. Robots also reduce waste by precisely dispensing solder and flux.

- For high-volume production, soldering robots are really the only viable option. They can work 24 hours a day, 7 days a week with zero breaks, cutting labor costs and improving productivity. They also pay for themselves, typically, in just 1-3 years.