What are multi-axis robots?

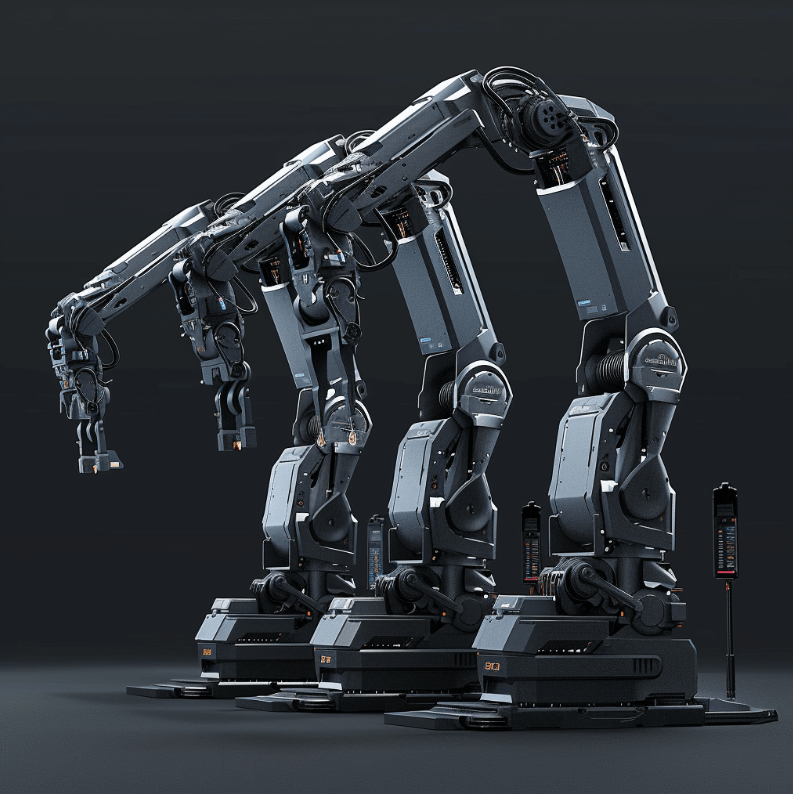

Multi-axis robots are automated arms with multiple joints that can move in different directions.

Unlike traditional industrial robots limited to 2 or 3 axes, multi-axis robots have 4 axes or more, giving them a greater range of motion and skill.

The axes of movement: Explained

Each axis controls a degree of freedom — that is, a range of movement. The more axes a robot has, the more it can do.

- Simple robots may have just two or three axes, allowing basic pick-and-place functionality. But as robots take on more complex tasks, additional axes become necessary. Today's most advanced robots can have seven axes or more, enabling a huge range of motion to complete intricate assemblies or manipulate objects in tight spaces.

- For example, a robot arm with three axes can move vertically, horizontally, and rotate. Add a fourth axis for gripping, and you have a robot that can grasp and move objects. Six or more axes allow for elbows, wrists, and fine finger control, similar to a human arm.

Some robot models even have axes that provide torso rotation or wheeled bases for mobility.

The possibilities expand exponentially with each new axis. That’s why multi-axis robots are so versatile and useful for applications like welding, painting, material handling, and electronics assembly where precision and flexibility are key.

The range of motion: From simple 2-axis robots to complex models with 7 or more axes

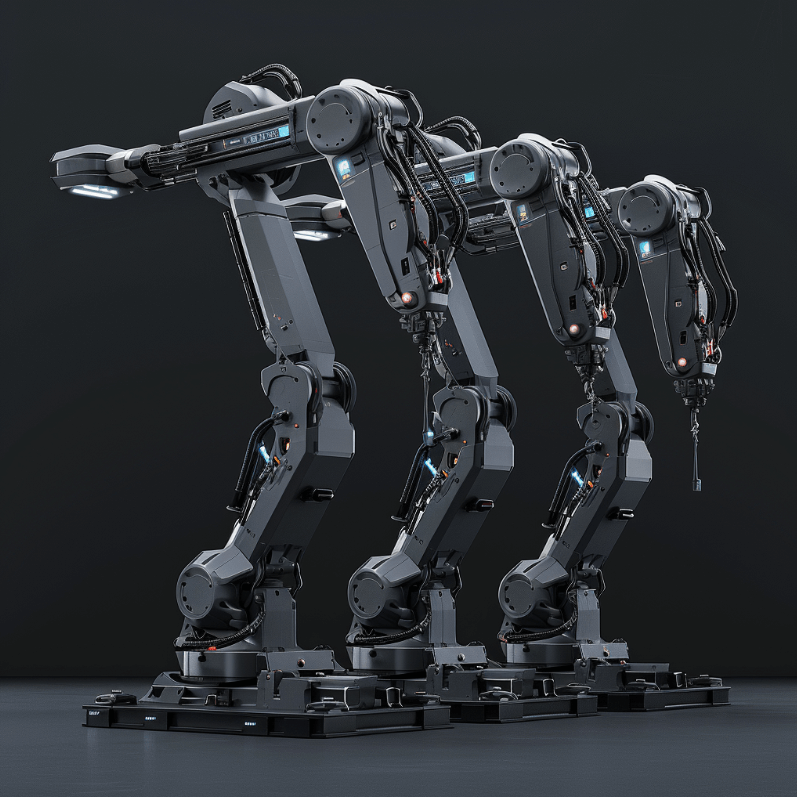

Let’s go into more detail about how more axes of motion enable a greater variety of possibilities:

- The simplest multi-axis robots have just two axes of motion. Think of a robot arm that can only move up and down and side to side. Two-axis robots are typically used for basic pick-and-place applications where precision isn’t critical.

They’re easy to program but limited in their capabilities.

- Robots with three axes of motion add a third rotational axis, like a human shoulder. They can move in an arc to pick up and orient objects. Three-axis robots are common in assembly line automation, where they handle repetitive tasks like packaging, palletizing, and machine tending.

- Highly articulated robots with six, seven, or more axes provide a full range of motion and an almost human-like dexterity. Robots with six axes or more can manipulate objects from multiple angles, allowing them to navigate obstacles and maneuver in tight spaces. They are well suited for complex assembly tasks, especially in industries like automotive manufacturing.

However, programming and controlling robots with many axes requires specialized software and skilled technicians.

Multi-axis robot applications & examples

Axis robotics may seem like a lofty concept, but it’s actually widely applied across major industries today.

Let’s take a look:

- Industrial automation. Multi-axis robots are widely used in industrial automation for repetitive and precise tasks. Their dexterity and range of motion allow them to handle complex assemblies, pick and place, welding, painting, and other applications that require coordinated movement. For example, a 6-axis robot can grasp an object, move its “arm” and “wrist” in all directions, and place the object with precision. This is ideal for assembling products on a production line.

- Medical applications. In the medical field, multi-axis robots assist surgeons in minimally invasive surgeries. Robotic surgical systems have multiple thin robotic arms that hold surgical instruments. The surgeon controls the robotic arms using a computer console, while viewing 3D images of the surgical area. This provides more skill and control than traditional techniques. Multi-axis robots are used for surgeries like hysterectomies, prostatectomies, and gallbladder removals.

- Space exploration. Advanced multi-axis robots have been used in space exploration for tasks that are too dangerous or complex for humans. The Mars Exploration Rovers Spirit and Opportunity, which landed on Mars in 2004, were six-wheeled robots with robotic arms for digging and examining soil samples. Future space missions may use multi-axis robots to assemble structures in space or explore harsh environments like Venus.

- Entertainment. You’ve probably seen multi-axis robot arms used in entertainment, from robot bartenders that can mix cocktails to animatronics in theme parks. While mostly a novelty, these applications showcase how dexterous and fluid robot movement has become. As robotics continue to advance, multi-axis robots will likely take on more roles in entertainment and customer service.