There are quite a few reasons why you should automate with robotic TIG welding.

Let’s take a look:

While TIG welding robots offer outstanding benefits, they do represent a pretty sizable investment. You must carefully weigh upfront and ongoing expenses to make an informed decision.

Here's what to keep in mind:

Bottom line: Robotic TIG welding offers a powerful way to elevate your fab shop's quality, productivity, and overall efficiency.

Choosing and installing a robot is the most important part of any TIG welding automation endeavor.

To get set up, here are the steps:

Then install the robot, power source, and wire feeder on a sturdy platform or frame near your welding stations.

With all the gear in place, you'll need to program the robot's control software with the specific welding parameters for your parts. This includes details like weld sequence, travel speed, amperage, and gas flow.

You'll teach the robot the correct motion path, weld timing, and weld positions for each joint.

Now, you’ll need to ensure your experienced human welders are best prepared to work safely and efficiently with their new automated colleagues.

Let’s take a look:

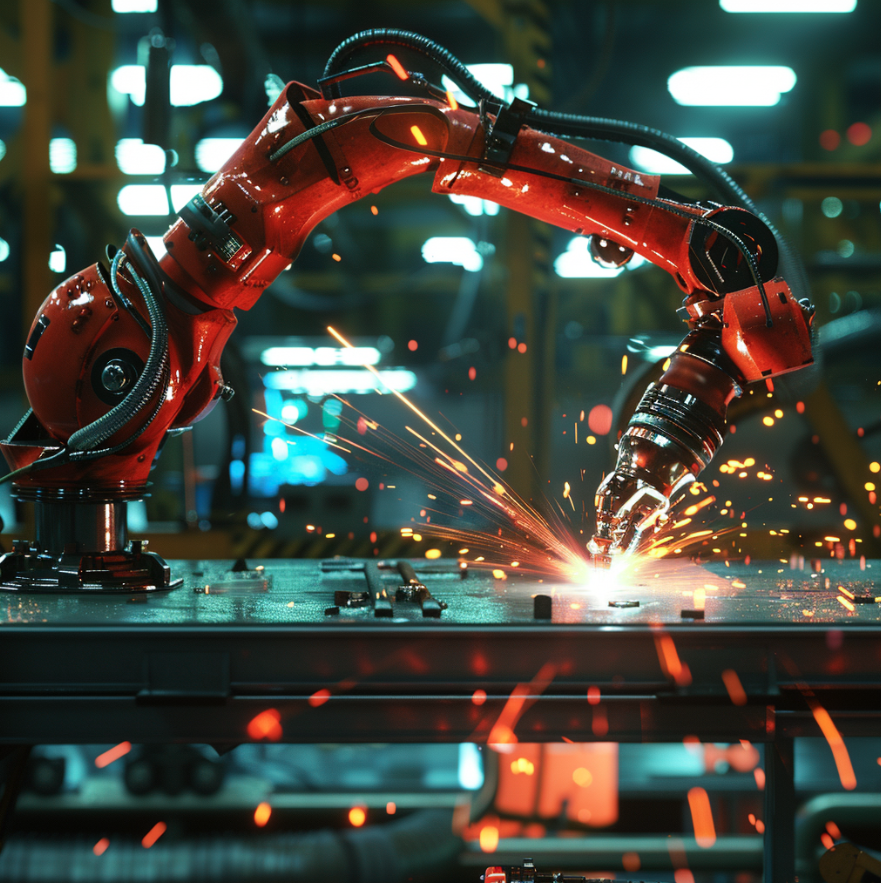

Robotic arms move at high speeds and conduct an arc welding process with extreme heat, so proper precautions must be taken.

With training covered, turn your attention to the many physical safeguards you can put in place to protect your workforce.

By the way: You can mitigate many common safety issues with robots by purchasing a “collaborative robot” or Cobot, such as RO1. These robots come with built-in collision avoidance and emergency stop functionality. Despite this, it’s worth taking stock of the possible hazards in working with welding robots.

Your robot’s manufacturer or your installation partner should be the ultimate source for information on a full safety solution, but here are our go-to tips for most fab shops:

So there you have it, a step-by-step plan for bringing automated welding technology into your factory and alleviating the pressures of a nationwide welding labor shortage.

While the process may seem daunting, by following this blueprint, you'll be up and running in no time. Once implemented, you'll immediately start to reap the benefits of increased productivity, improved weld quality, and cost savings.

Not to mention, your welders will appreciate being freed up to focus on the more complex, intricate welds that still require a human touch!

Interested in bringing robotic TIG welding to your own business? RO1 by Standard Bots is the best choice for fab shops large and small:

Speak to our solutions team today to arrange a free 30-day on-site trial and get expert advice on everything you need to deploy your first robot.