You’ve probably heard of MIG welding before: It's one of the most common welding processes.

But what about MAG welding? If you're scratching your head wondering what the difference is, you're not alone. Many people (not welders, though!) use the terms interchangeably, but MIG and MAG are actually two distinct processes.

In this article, we'll break down exactly what MAG welding is, how it works, and how it differs from MIG welding.

We’ll cover:

- What is MAG welding?

- How does it work?

- An overview of MAG vs MIG Welding

- MAG welding cases in several industries

- Can you automate MAG welding?

Let’s dive right in!

What is MAG welding?

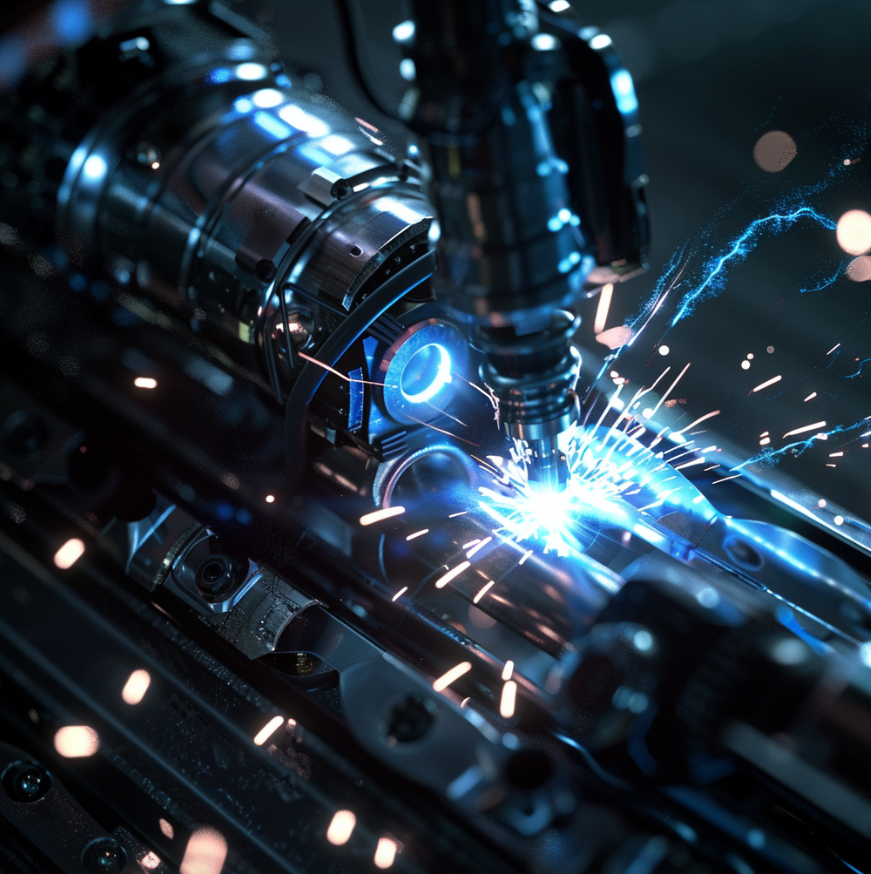

MAG welding, or metal active gas welding, is a type of arc welding that uses an active shielding gas like carbon dioxide or argon and hydrogen to protect the weld pool from atmospheric gasses.

The shielding gas plays an active role in the welding process, chemically reacting with the molten weld pool.

How does MAG welding work?

So how does MAG welding actually work?

The key is an electric arc that forms between a wire electrode with a continuous feed and the base material. The heat of the arc melts the wire and the base material, fusing them together.

Here’s how the magic happens:

- Shielding gas magic! To protect the weld pool from contamination, the shielding gas goes through the gun. Argon and carbon dioxide are commonly used — the gas shields both the molten weld pool and the arc from the air.

- All filler, no killer. A wire electrode, typically made of steel, acts as the filler metal. It's continuously fed through the welding gun and into the weld pool. There, it melts and fuses with the base material. As the weld forms, the gun moves along the joint.

- Powering things up. A constant voltage power source provides the electrical energy to maintain the arc. The arc, in turn, melts the wire and base material. As the wire is fed through the gun, the arc is maintained at a steady voltage.

- Shooting from the hip. The weld gun directs the electrode, shielding gas, and arc to the weld joint. A trigger controls the speed at which the wire is fed and the flow of shielding gas. Using the gun, the welder can manipulate and direct the arc and weld pool.

MAG vs MIG welding

When it comes to welding, you’ve probably heard of MIG and MAG welding, but what exactly is the difference?

In short, MIG stands for metal inert gas welding, while MAG refers to metal active gas welding. The main distinction between these two arc welding processes is the type of shielding gas used.

- Different gasses for different folks. MIG welding uses inert gasses for shielding, such as argon or helium that do not chemically react with the molten weld pool. MAG welding uses an active shielding gas, typically a mixture of argon and carbon dioxide, that does react with the weld pool. The active gas helps stabilize the arc and gives better weld penetration.

- Some pros and cons. MAG welding produces welds that tend to be stronger and deeper penetrating than MIG welds. However, the reactive shielding gas can lead to more spatter and fumes. MIG welding with an inert gas produces cleaner, spatter-free welds but may lack the all-around strength and depth of MAG welds.

- When do you even use each? Use MIG welding when you need an aesthetically pleasing, spatter-free weld, such as welding sheet metal. Conversely, give some thought to MAG welding for welding thicker materials or when weld strength is critical, such as structural welding. Also, MAG welding tends to be a bit more economical since carbon dioxide is less expensive than argon.

- Automation. Both MIG and MAG welding can be automated using mechanized equipment like welding carriages, boom arms, and welding robots. Automated MAG welding, in particular, is commonly used for high-volume production applications in industries like auto manufacturing.

| |

MIG Welding

|

MAG Welding

|

|

Shielding Gas

|

Inert gasses (e.g., argon, helium)

|

Active gasses (e.g., argon + carbon dioxide)

|

|

Gas Reaction

|

Does not react with molten weld pool

|

Reacts with molten weld pool

|

|

Weld Quality

|

Cleaner, spatter-free welds

|

Stronger, deeper penetration, but more spatter and fumes

|

|

Ideal Use

|

Aesthetically pleasing welds on sheet metal

|

Strong welds on thicker materials or where weld strength is critical

|

|

Cost

|

More expensive due to inert gas

|

More economical due to cheaper active gas

|

|

Automation

|

Can be automated

|

Often automated, especially in high-volume industries like auto manufacturing

|

MAG welding use cases across diverse industries

You may be saying to yourself: “This is all well and good, but who is using MAG welding in the real world?”

Glad you asked, because we’ve got some real-world use cases for you:

- Keeping the auto industry together. The auto industry relies heavily on MAG welding for manufacturing vehicle bodies and frames. The high deposition rates and faster travel speeds of MAG welding make it ideal for joining large sections of sheet metal.

You'll find MAG welds on everything from fenders and doors to chassis and suspensions.

- Keeping the ship afloat. For similar reasons, shipbuilders frequently use MAG welding. It allows them to join huge steel plates for hulls and decks in a timely and cost-effective manner. The high heat input also produces welds that can withstand the extreme forces experienced in marine environments.

MAG welding produces the continuous, watertight seams necessary for sea vessels.

- Heavy-duty machinery. The heavy machinery industry depends on MAG welding to build massive components like crane booms, bulldozer blades, and tractor frames. MAG's high deposition rates and penetration are pretty much essential for achieving strong, durable welds on dense, thick materials. This is doubly important when manufacturing equipment that will undergo intense strain and loading.

MAG welds are also often used to join dissimilar metals in heavy machinery.

- Building those long pipelines. For constructing long-distance pipelines, MAG welding is the most efficient and productive process available. It can produce the long, continuous seams needed to join sections of pipe. MAG also provides the penetration required for high-pressure, high-temperature applications like oil and gas pipelines.

Automated MAG welding systems are frequently used in pipeline construction to maximize speed and ensure weld consistency over long lengths.

- Steel construction. MAG welding is everywhere in steel construction and fabrication. It’s used for joining wide flange beams, channel sections, square and round tubes, and plate girders. MAG produces full penetration welds and minimal distortion, which are essential qualities for load-bearing steel structures. It also allows for high deposition rates and faster travel speeds to maximize productivity.

You'll find MAG welds in everything from steel-framed office buildings to stadiums, bridges, and towers.