Industrial automation refers to using machines, control systems and information technologies to handle industrial processes with as little human assistance as possible.

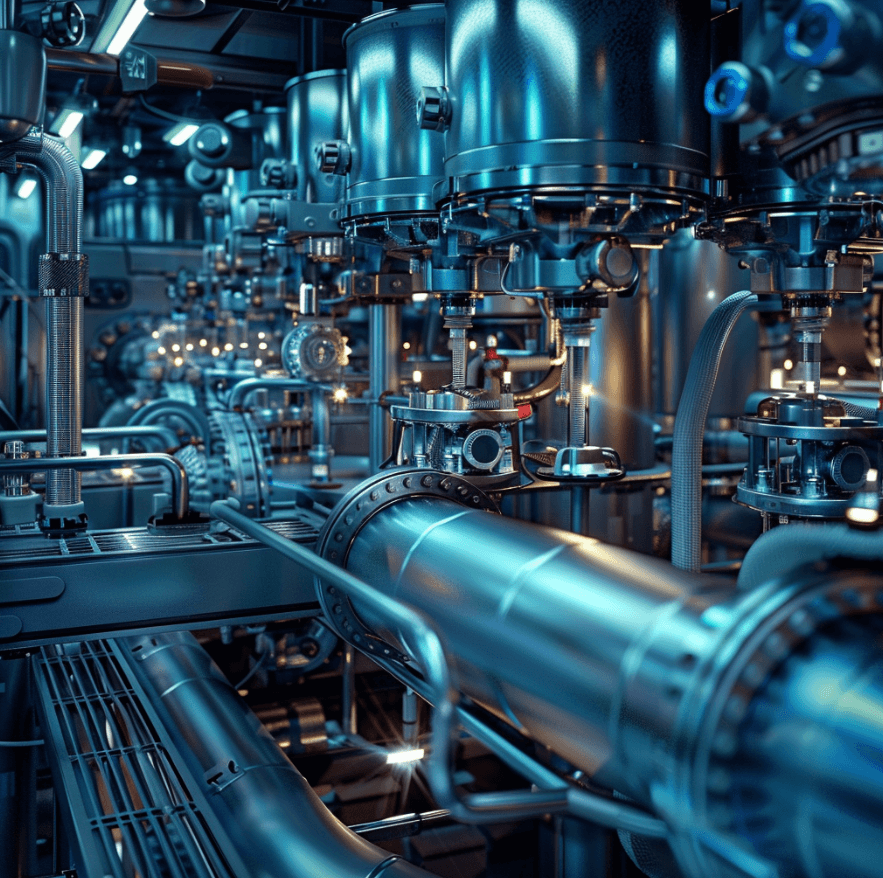

As a factory owner, implementing automation means your equipment and machinery can largely operate on their own using control systems like sensors, embedded devices, and actuators.

If you own a factory, industrial automation should 100% be on your radar.

Here are a few reasons why:

There are several approaches companies can take to automate their operations.

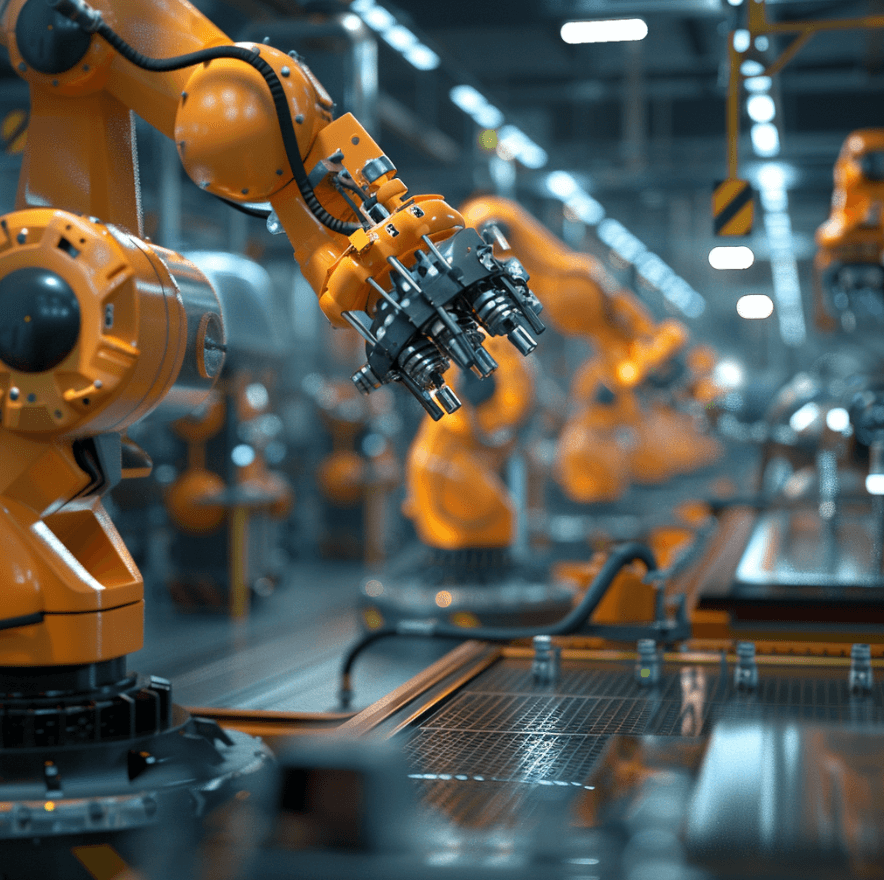

Industrial robots can keep going almost indefinitely — apart from the one or two short maintenance breaks.

They’re extremely precise and consistent, producing high-quality work. They can perform repetitive, dangerous, and difficult tasks that humans would rather not do (even if the pay is good).

If you're just getting started with automation, industrial robots are a great place to start. Many robotics companies offer "collaborative robots" or "Cobots" that are super easy and intuitive to program and deploy.

Cobots can work side-by-side with humans with no need for safety cages. Also, they’re very flexible and can be reprogrammed to perform different tasks.

As a rule of thumb, Cobots are more affordable and easier to implement than traditional industrial robots. Mostly, that comes down to intuitive interfaces and practically zero need for a specialized coding background.

This makes them accessible even for small businesses!

Logistics systems are all about optimizing the flow of raw materials and finished goods. For many factories, logistics can be one of the biggest costs and headaches.

Automating your logistics with bots and software can massively bring down costs.

You have a few options for automating logistics:

Quality Control Systems stand out as the eagle-eyed watchdogs of productive processes.

How? By using cutting-edge vision systems and precise sensors, these systems scrutinize every minute detail of products moving down the line, quickly spotting and flagging any imperfections.

This not only ensures that the final product meets the stringent quality standards consumers expect but also significantly minimizes waste by catching errors early in the production process.

Order picking innovations totally streamline the picking process, which enables a rapid and accurate retrieval of products for shipping.

All in all, by integrating robotic technology, warehouses can significantly reduce the time spent on fulfilling orders, minimize errors, and enhance overall operational throughput.

This automation also enables a smoother flow of goods from warehouse to customer — a cornerstone of meeting the increasing demand for quick delivery times in today’s ecommerce-driven market.

Assembly line automation is replacing the monotony of manual labor with the precision and delightful consistency of robotic arms and automated equipment.

Assembly line automation can rock out on a variety of assembly tasks — from simple component placement to complex product assembly — with absolute accuracy and speed.

The result? A significant oomph in production efficiency and a drastic reduction in human error.

The first step is to evaluate your production processes and identify areas that would benefit most from automation — the low-hanging fruit.

As a rule of thumb, look for repetitive, mundane tasks that need speed, precision, or round-the-clock operation.

Some areas ripe for automation include:

Now, once you’ve identified key areas, you’ll need to assess which options make sense for your needs and budget.

Basic automation like Conveyors or pick and place robots are relatively affordable.

Conversely, advanced systems with robotic arms, AGVs and automated inspection will need a much larger upfront investment — but can yield yummy long-term benefits.

By now, you should have a solid understanding of what automation is, the major benefits it offers, and the different types of automation solutions to consider.

After that, the next step is to take a close look at your manufacturing operations and identify where automation can drive the most impact.

Start small with a pilot project, learn from it, and then scale up from there!

Looking to elevate your shop floor with industrial automation? Standard Bots' RO1 shines as a leader in the Six-Axis articulated robot arm space, perfectly suited for both burgeoning businesses and industry giants.

Our dedicated team is on hand to assist in seamlessly incorporating RO1's cutting-edge capabilities into your shop floor. Try it now with our no-risk 30-day trial!