Fixed automation, also known as “hard automation” refers to automated equipment that is installed permanently in a fixed location and designed to perform a specific processing task repeatedly.

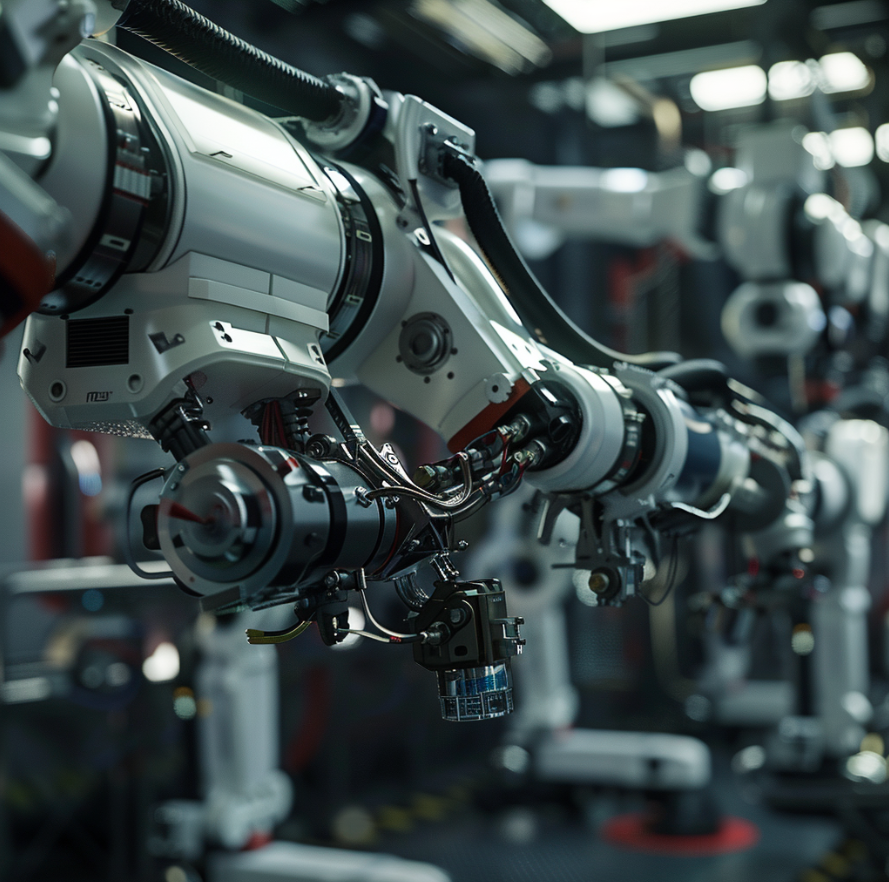

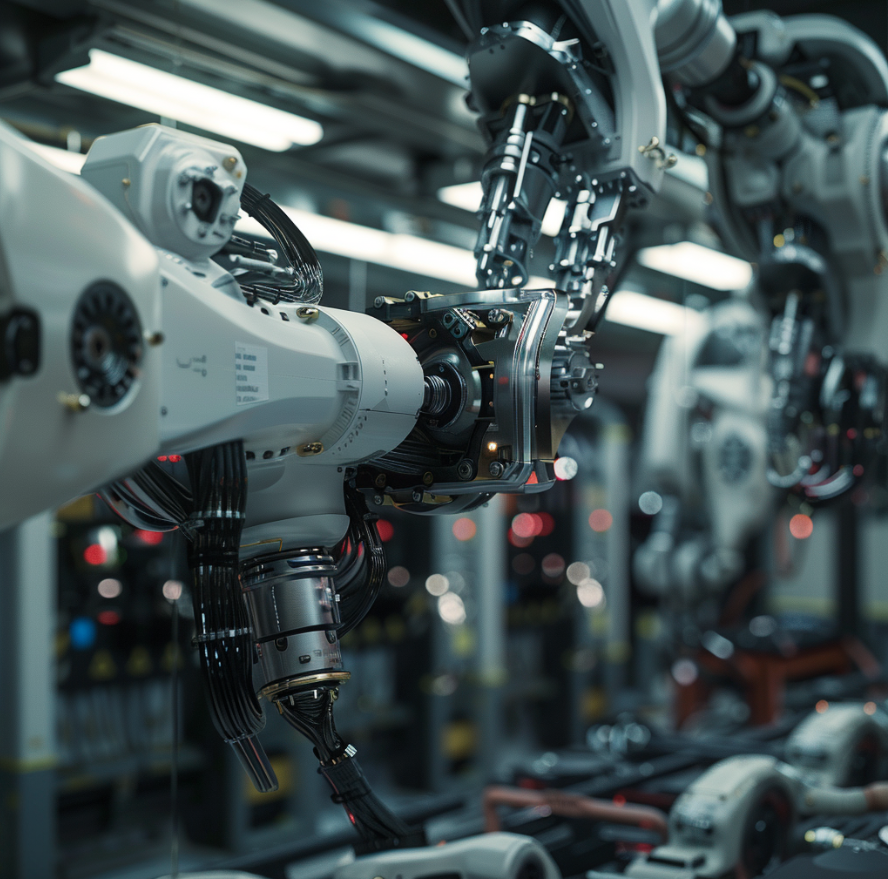

If you’re having trouble picturing it, just think of the massive assembly lines used to produce vehicles — that's fixed automation for you.

The main features of fixed automation:

Fixed automation is definitely different from other types of automated systems, like programmable and flexible automation in that it’s designed to do a specific, unchanging task repeatedly — pretty much until the wheels fall off.

So, once installed, fixed automation can’t be easily adapted or reconfigured. As a result, it’s better suited for high-volume production of standardized goods.

As you’ve probably gathered, fixed automation is already widely in use across a tremendously large range of industries.

Here are some fixed automation examples.

Fixed automation offers several excellent benefits for many manufacturing and industrial applications.

Let’s take a look:

Fixed automation is highly efficient since the equipment is designed to perform a specific task with extreme speed and the highest levels of repeatability. So, once the process is set up, it can operate continuously without breaks at a fast, consistent pace. The result? High throughput and productivity.

Fixed automation systems are typically very reliable. Since they have a limited range of functions, fewer components can malfunction or break down. They’re also designed to handle high volumes over a long lifespan. This means that, with regular maintenance, fixed automation can provide years of uninterrupted service.

Although fixed automation requires a large initial capital investment, it becomes very cost-effective over the long run. Labor costs go way down because human operators aren’t required to oversee or control the equipment. Meanwhile, the energy usage can also be optimized for maximum efficiency.

The high throughput and minimal downtime mean a quick return on investment — just 1-3 years!

Fixed automation is a godsend for tasks that require a high degree of precision, quality, and consistency. The automated equipment is programmed to perform the exact same steps the exact same way every single time. This results in a standardized process and output that rarely varies. Products are produced uniformly at a predictable rate with minimal defects or errors. Quality control is also simplified — there are fewer variables in the system.

Yes, fixed automation has some downsides to be aware of. Since the systems are designed for highly specific tasks, they lack flexibility. Once installed, the configuration of a fixed automation system is difficult and expensive to change.

So, if your production needs change, the system may need major overhauls or even total replacement to adapt. A major headache!

Here are the most important limitations of fixed automation to address head-on before you invest in a system:

Let’s recap: Fixed automation is all about using specialized machines to repeatedly do the same tasks over and over.

And, while it lacks flexibility, fixed automation can't be beat for efficiency and precision when it comes to high-volume, low-variety production.

But it’s not all sunshine, rainbows, and daisies: Its rigid nature makes changeovers extremely difficult and costly, so you've got to be sure the product or process you're automating will have a long, stable lifecycle.

Still, when applied wisely to the right situations, fixed automation will enable companies to maximize throughput and slash costs.

Now you know the ins and outs, you can determine if fixed automation is the right fit for your operation.

Designed to level the playing field for businesses of all sizes, RO1 by Standard Bots delivers powerful automation capabilities previously inaccessible to many companies.

Our experts are with you every step of the way to guarantee a smooth transition and maximize the return on your RO1 investment. See it for yourself with our 30-day risk-free trial!