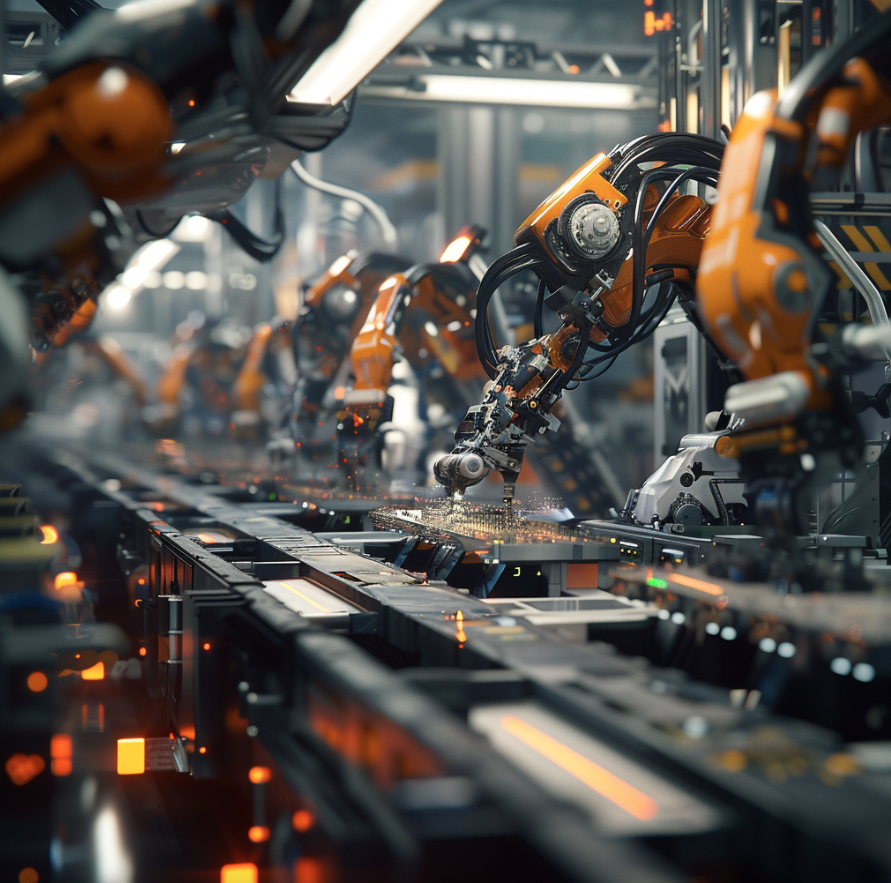

A high-speed Pick and Place robot is an automated system designed to quickly grab and move objects with precision.

These robots use robotic arms fitted with custom grippers to pick up components, parts or products and place them accurately at really high speeds.

High-speed Pick and Place robots are engineered to operate at exceptional speeds, often exceeding 150 cycles per minute, compared to traditional robotic systems that might only perform around 30 to 60 cycles per minute.

These advanced robots can handle delicate components with precision, placing them with accuracies within 0.1 mm.

They are designed with lightweight materials and use sophisticated servo motors, which enable rapid acceleration and deceleration without compromising on accuracy or causing damage to the products.

Furthermore, their integration with high-resolution vision systems allows for the real time tracking and handling of objects at speeds that manual labor or conventional machinery just cannot match.

The cost of a high-speed Pick and Place robot can vary a huge deal depending on its specifications and capabilities.

First, you'll want to consider not just the initial purchase price of the robot arm, but also the additional costs like integration, end-of-arm tooling, and safety mechanisms.

Base robot arms typically start around $30,000 to $200,000 for a standard model with a decent payload and reach. Higher-performance arms with higher speed, precision, and customization can cost $250,000 or more.

Now, some of the fastest Pick and Place robots on the market today boast cycle times under 0.15 seconds but come with a huge price tag of over $500,000.

Once you've picked your robot you'll need to integrate it into your production line and equip it with end-of-arm tooling suited to your needs – which could add $10,000 to $50,000 or more to your total cost depending on the complexity.

You may also need to invest in safety mechanisms like light curtains, emergency stops, and protective fencing which can cost between $5,000 to $30,000 to implement.

Then, there are the additional costs, like maintenance fees, spare parts, and periodic software upgrades which are often needed to keep your bot in tip-top shape. to keep your robot operating at peak performance.

Then, there’s the possibility of having to train your robot operators, which also depends on the robot’s complexity.

The good news? Automation typically pays for itself in 1-3 years.

The most important thing is determining how fast you need the robot to operate and how delicate the parts are that it will be handling.

Keep these factors in mind:

Standard Bots' RO1 joins the fray of high-speed Pick and Place robots, with impressive features and an attractive price tag.

Price: Starting at half the price of its nearest competitors, and with a $5/hr lease model, it leads the pack in affordability and reliability.

This line of robots may not be exactly the most well-known, but they’ve got the goods when it comes to delivering high-speed pick and place operations.

Price: Estimated starting price: Around $40,000 (may vary depending on configuration and options).

Yaksawa almost needs no introduction for robotics enthusiasts, and their GP165R is a modern pick and place marvel.

Price: Similar to the ABB IRB 660, the price of the Yaskawa Motoman GP165 varies depending on specific configurations and requirements. Estimates suggest a starting price range of around $25,000.

High-speed Pick and Place robots can operate at up to 200 picks per minute, much faster than human workers. The fastest models use advanced vision systems and motion control to swiftly grab and place items with a high degree of accuracy.

These robots are designed to handle small parts, components, and packaged goods. They can pick up items as small as a grain of rice or as large as a shoebox with vacuum grippers or mechanical claws. Soft, fragile, and irregularly shaped goods may require specialized end-of-arm tooling.

High-speed Pick and Place robots range from $50,000 up to $500,000 or more, depending on the speed, number of axes, payload, and options. Additional costs include programming, installation, integration, and safety mechanisms. For many manufacturers, the increased productivity and reduced labor costs provide a good return on investment.

Modern high-speed Pick and Place robots feature intuitive programming interfaces that don't require advanced robotics knowledge. However, achieving fast, precise, and synchronized movement does require skilled integration and optimization. Most suppliers offer programming, installation, and training services to help get your robot line up and running as quickly as possible.

Yes, with proper safeguarding and fencing, high-speed Pick and Place robots can work cooperatively with human workers – although Collaborative robots (or Cobots) don’t need these. Safety mechanisms like light curtains, emergency stops, and reduced speed/force modes help prevent collisions and injury.

Many robot models also offer adjustable safety ratings so you can tailor their operation to specific applications. Proper training and clear communication are important to effective human-robot collaboration.

From understanding how these amazing machines work to figuring out if investing in one is the right move for your production line, we covered all the bases about high-speed Pick and Place robots.

And with the top recommendations and tips for choosing the perfect bot for your needs, you're armed and ready to start automating – provided you’ve got the budget, that is!