Robotics integrators are companies that specialize in designing, programming, and implementing customized robotic solutions for businesses. They handle everything from consulting and design to installation, training, and support.

So, instead of buying an off-the-shelf robot, robotics integrators work with you to create an automated system that suits your needs.

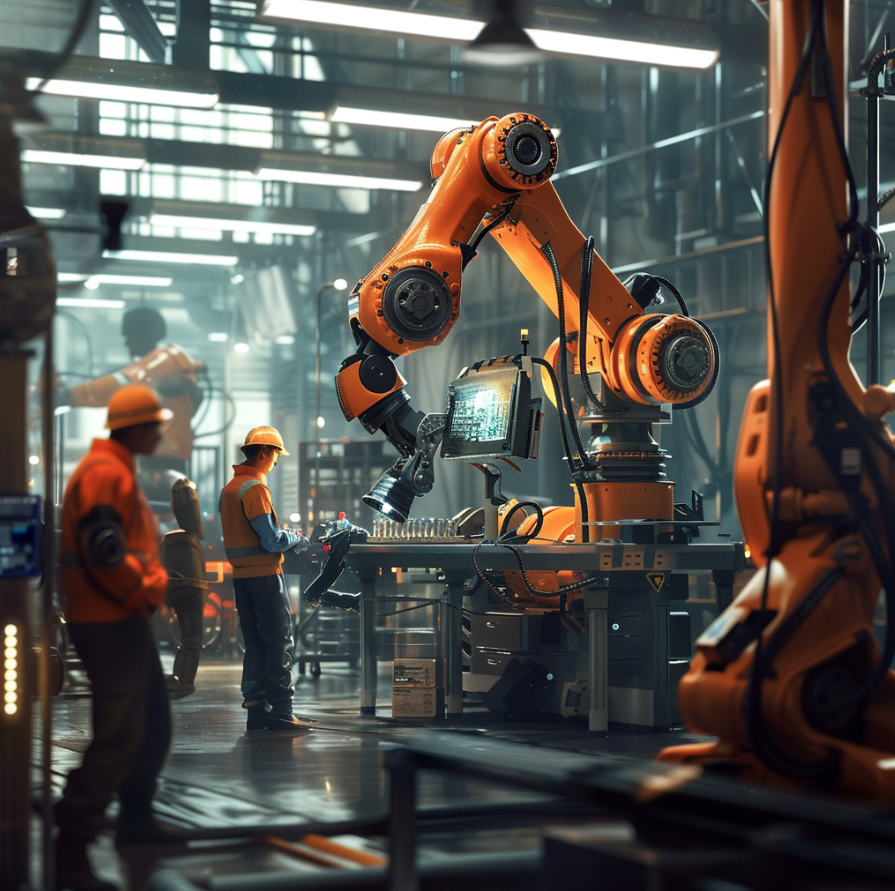

How? They determine the best robotic technologies - like Collaborative robots (Cobots), Articulated arms, or Autonomous Mobile Robots (AMRs) - that your applications need.

The integrators then program the robots, test the system, install it on your production floor, and make sure your team is fully trained to operate it.

A robotics integrator can take your automation vision and make it a reality by handling all the nitty-gritty details so you can focus on your business.

Specifically, an integrator will:

Basically, using a robotics integrator eliminates the headache of tackling a complex automation project yourself – for a cost, of course.

Robotics integrators can be a huge help for companies that want to take the automation plunge. But how do you know whether working with an integrator is exactly what your business needs?

Start by checking items off this list first:

Designing an automated system from scratch requires a pretty big time and financial investment.

However, integrators have already developed solutions for common automation tasks that they can adapt to your needs.

This allows you to get up and running faster without reinventing the wheel. They also have relationships with robotics suppliers to get you the best possible pricing.

Robotics integrators have a tremendous wealth of specialized, technical knowledge that would take you years to develop in-house.

They stay on the cutting edge of new technologies and best practices in automation. Tapping into their expertise is a surefire way to gain a competitive advantage.

Experienced integrators know how to avoid common pitfalls and have proven methodologies to guarantee that you’ll complete your automation project on time – and on budget.

They can also provide support after installation to maximize uptime. Without their know-how, you risk costly errors, downtime, and not getting the most out of automation.

That said, working with an integrator may not make sense if you only have a small project, limited budget, or resources to dedicate to it.

You’ll need to think long and hard about the scale of your needs, in-house capabilities, and how much control you want over the process.

If you have a complex project or lack automation experience, an integrator is probably your best bet. But for a straightforward task, you could save money by handling it in-house with their guidance.

So you’ve decided that working with a robotics integrator is the right move for your automation project.

But, now comes the hard part - finding the perfect partner in crime!

Take a look at these tips to find the right fit for you:

This direct feedback is gold - it tells you what they’re really good at, where they might fall short, and whether they’re worth calling back at all.

Now you know what a robotics integrator is, what they can do for you, and why working with one makes sense for many companies looking to automate.

The hard part is finding an integrator you mesh with that can truly customize a solution for your needs, timeline, and budget.

But, with this guide in hand, we have no doubt you’ll do just fine!

Want to skip the hassle of hiring a robotics integrator? Automate your shop floor with Standard Bots’ RO1, and we’ll do it for you!

Go for a free 30-day trial to experience firsthand how RO1 melds AI flexibility with robotic power. Our expert team is ready to guide you in seamlessly incorporating RO1's advanced technology into your workflow.